GRAINS

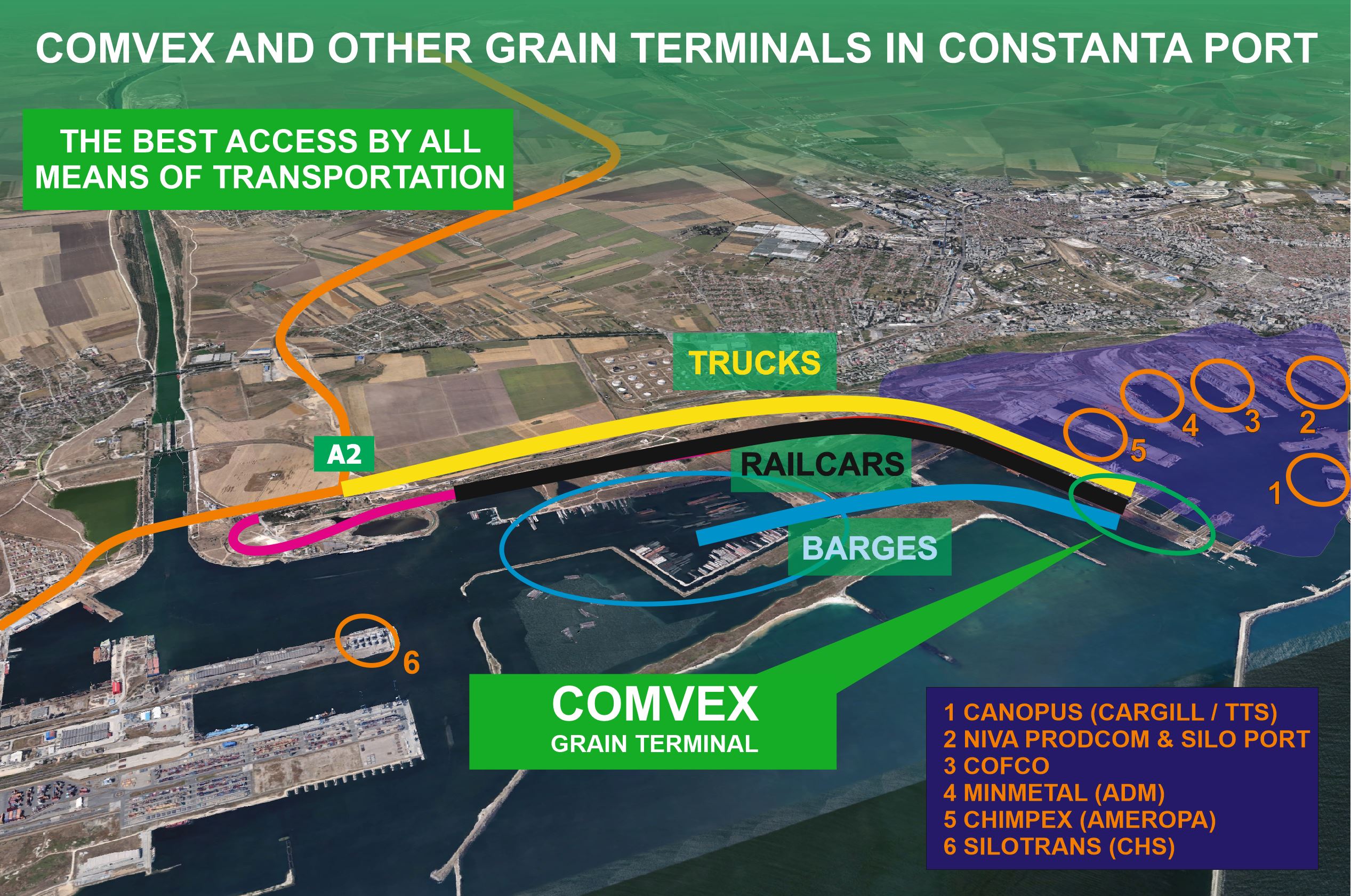

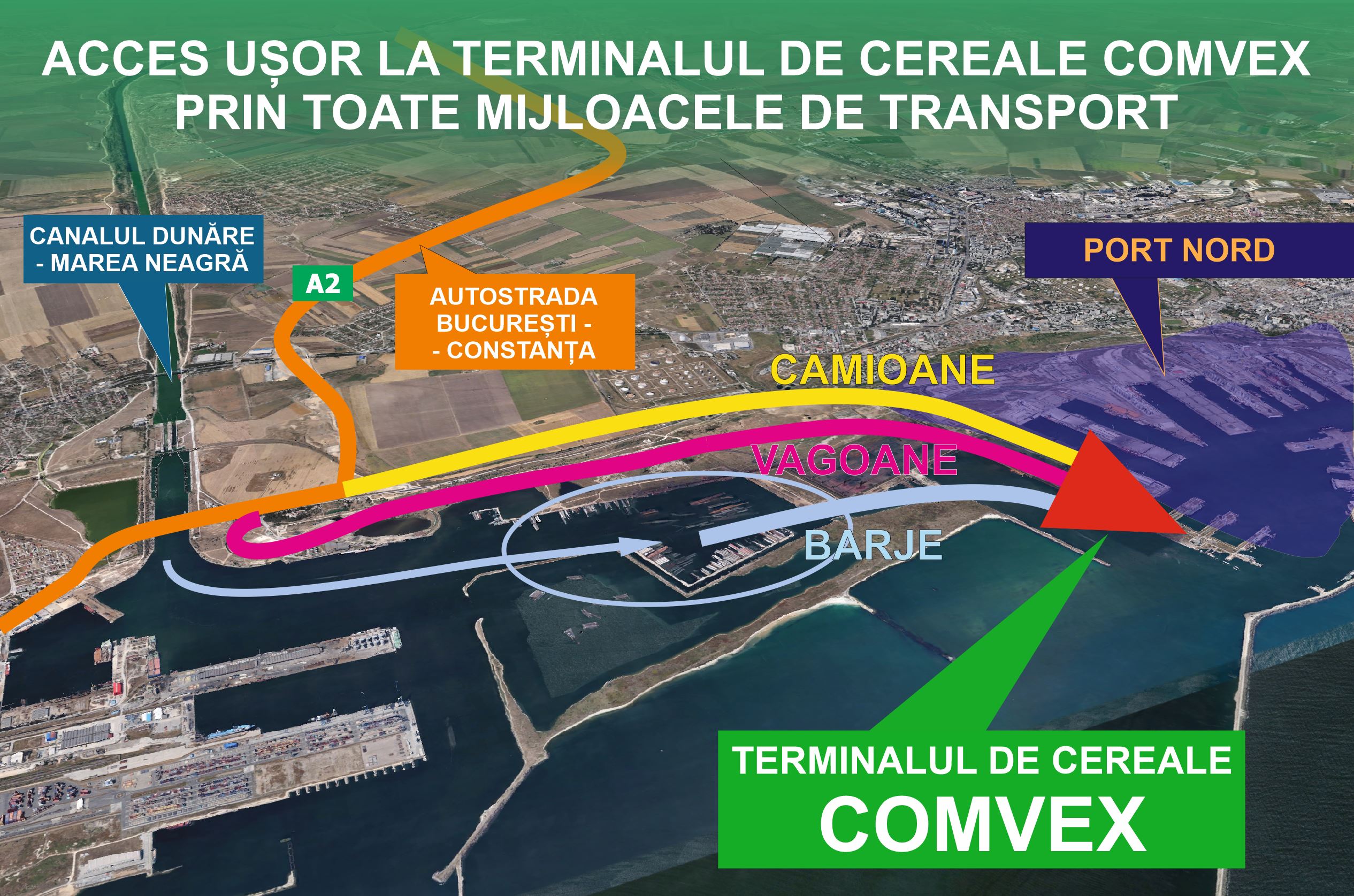

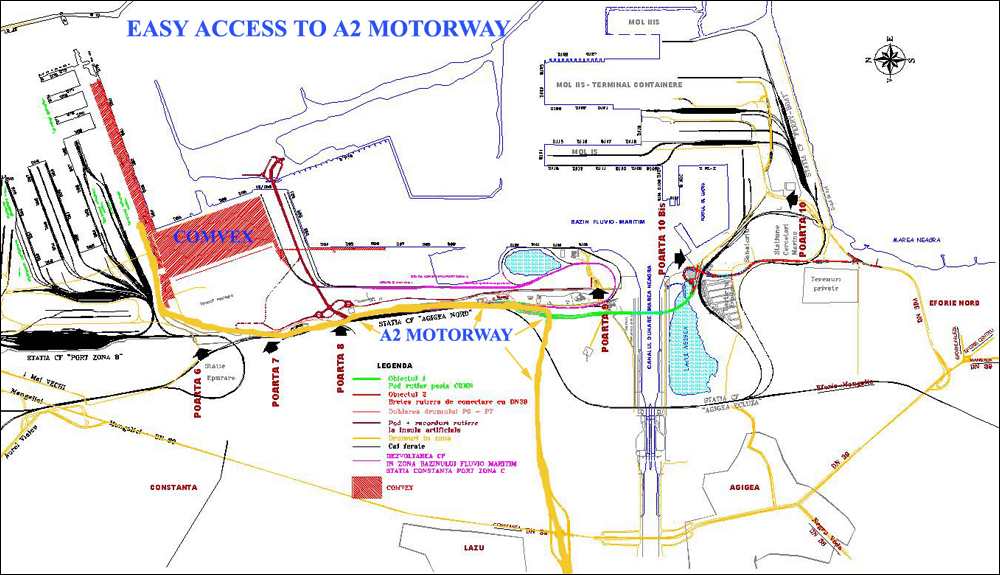

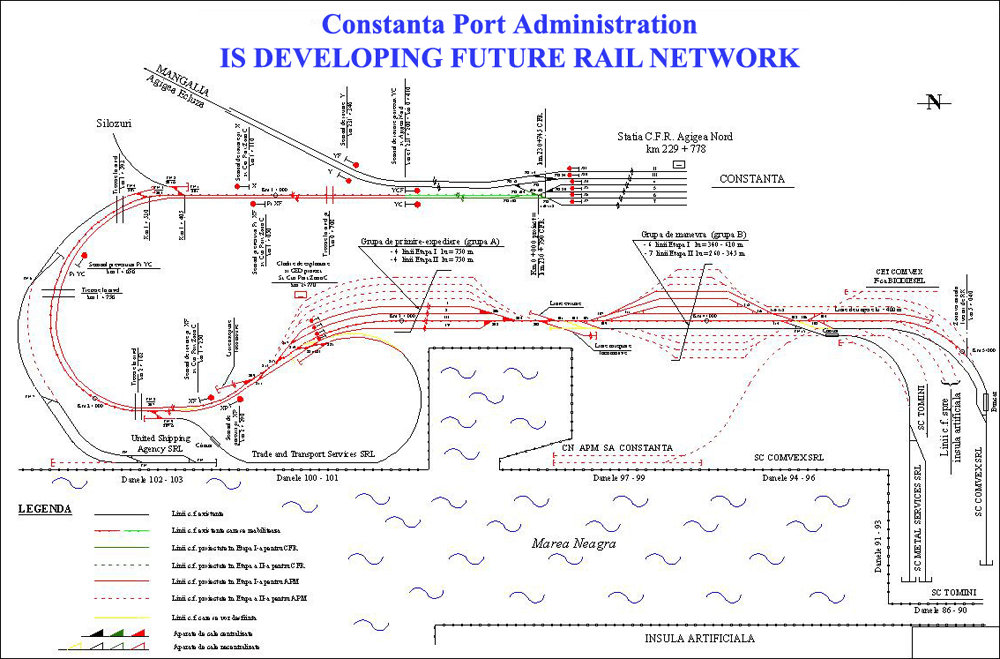

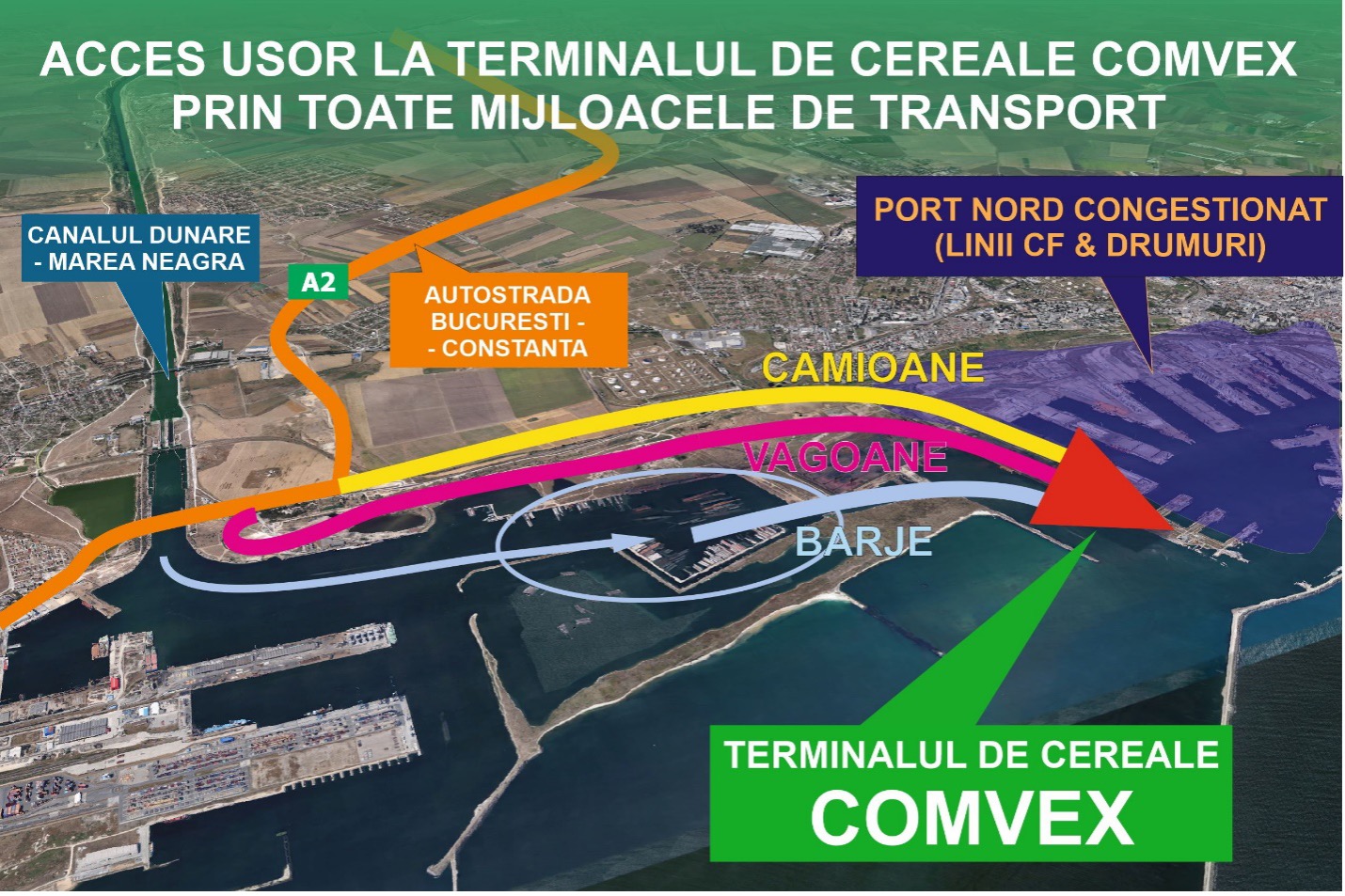

STRATEGIC POSITION OF CGT

CGT is connected to all three incoming transportation ways: Danube River, national railway and road. The location provides important logistics advantages, respectively: the deepest berth in the Black Sea, vicinity with the barge terminal for river transport from countries alongside Danube River, direct and easy access to the railway, short distance and direct access from/to highway A2. Thus, COMVEX provides grain producers from Romania, Hungary, Serbia, Bulgaria, Ukraine and Moldova with the possibility to deliver the local grain production on ships of large capacity, up to 100,000÷120,000 tdw (250 m length and 42 m width).

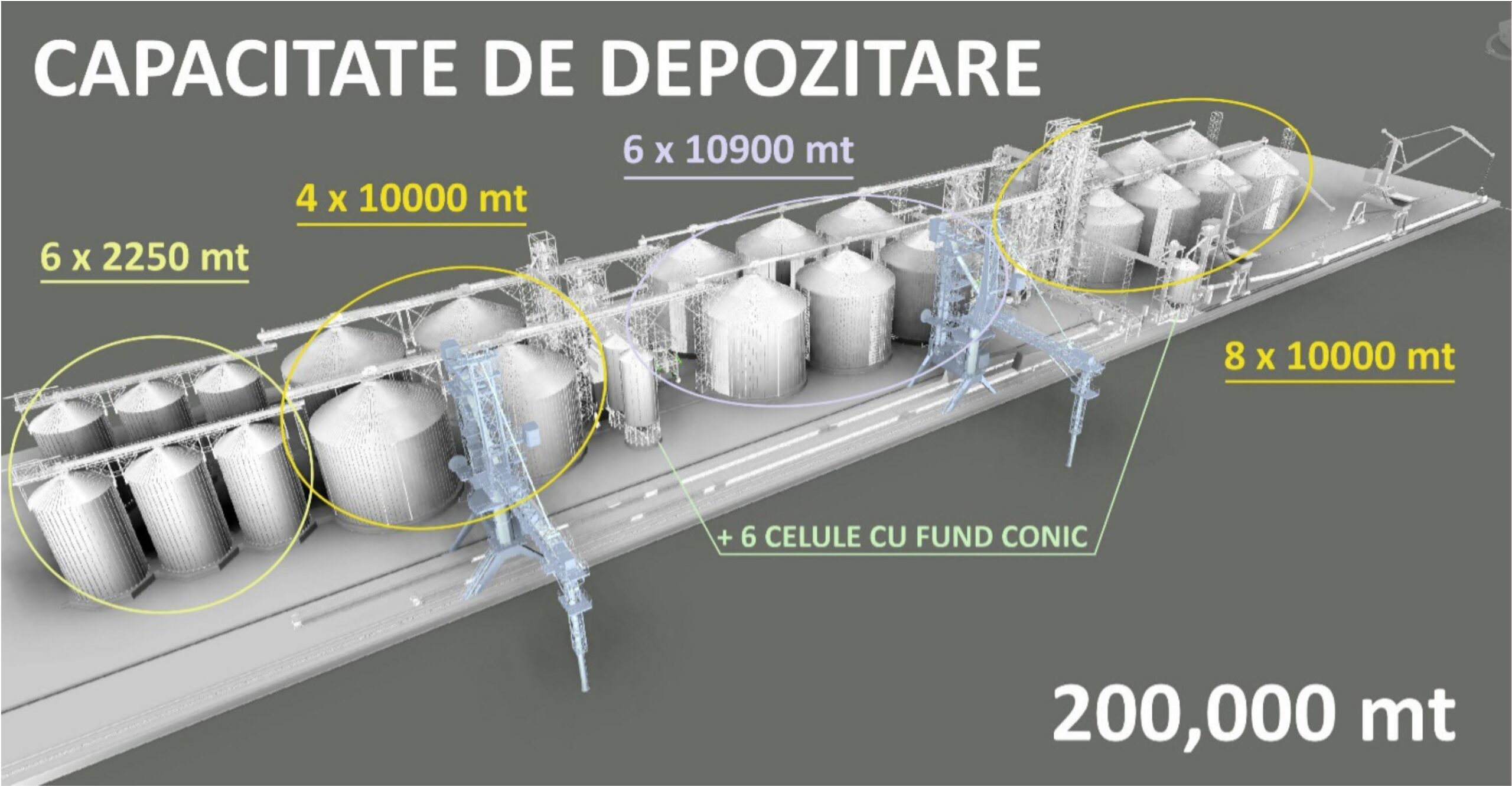

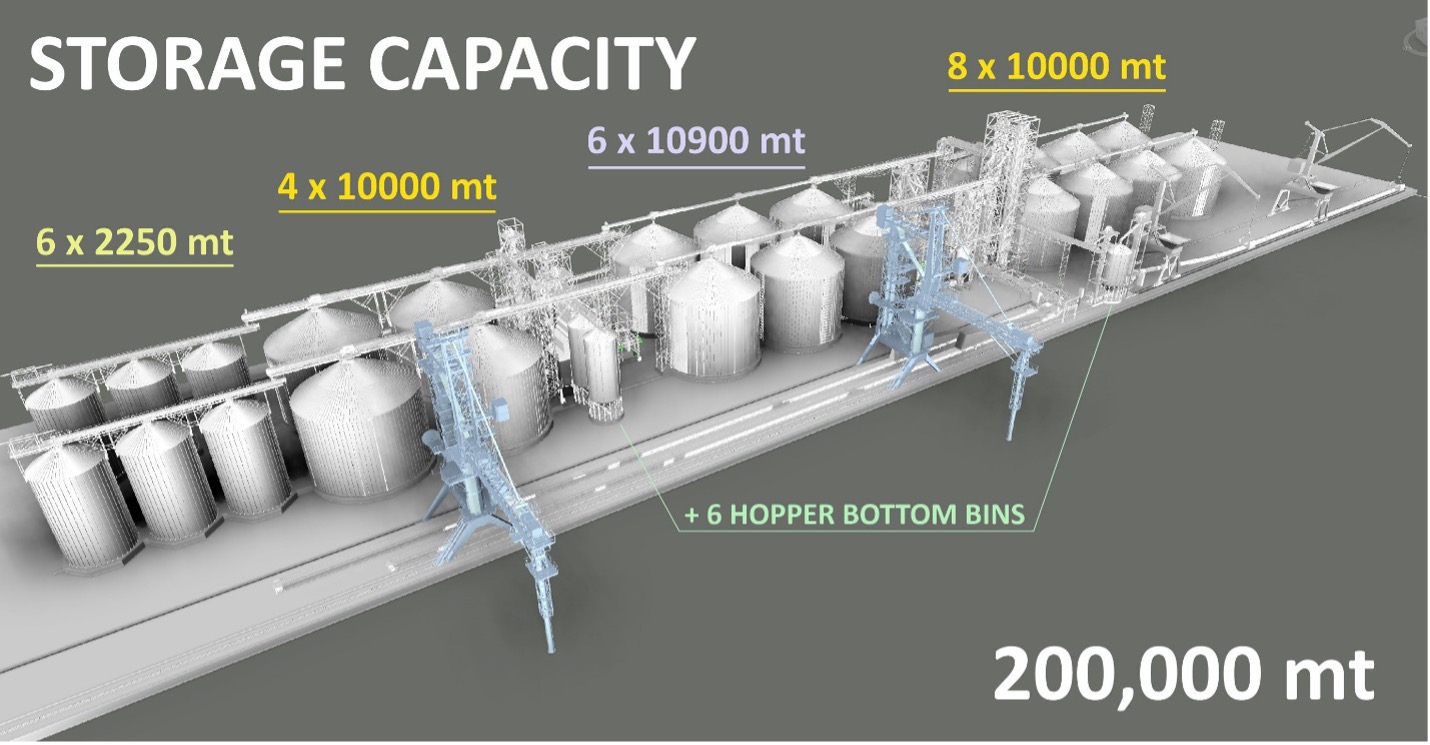

STORAGE CAPACITY

Total storage capacity of CGT is 200,000 mt. All storage capacities and handling capacity rates are based on wheat.

Grain storage area comprises 18 large flat bottom bins (12 x 10,000 mt and 6 x 10,900 mt), 6 small flat bottom bins (each 2,250 mt) and 6 hopper bottom bins.

The layout of CEGT provides a high handling flexibility of the terminal.

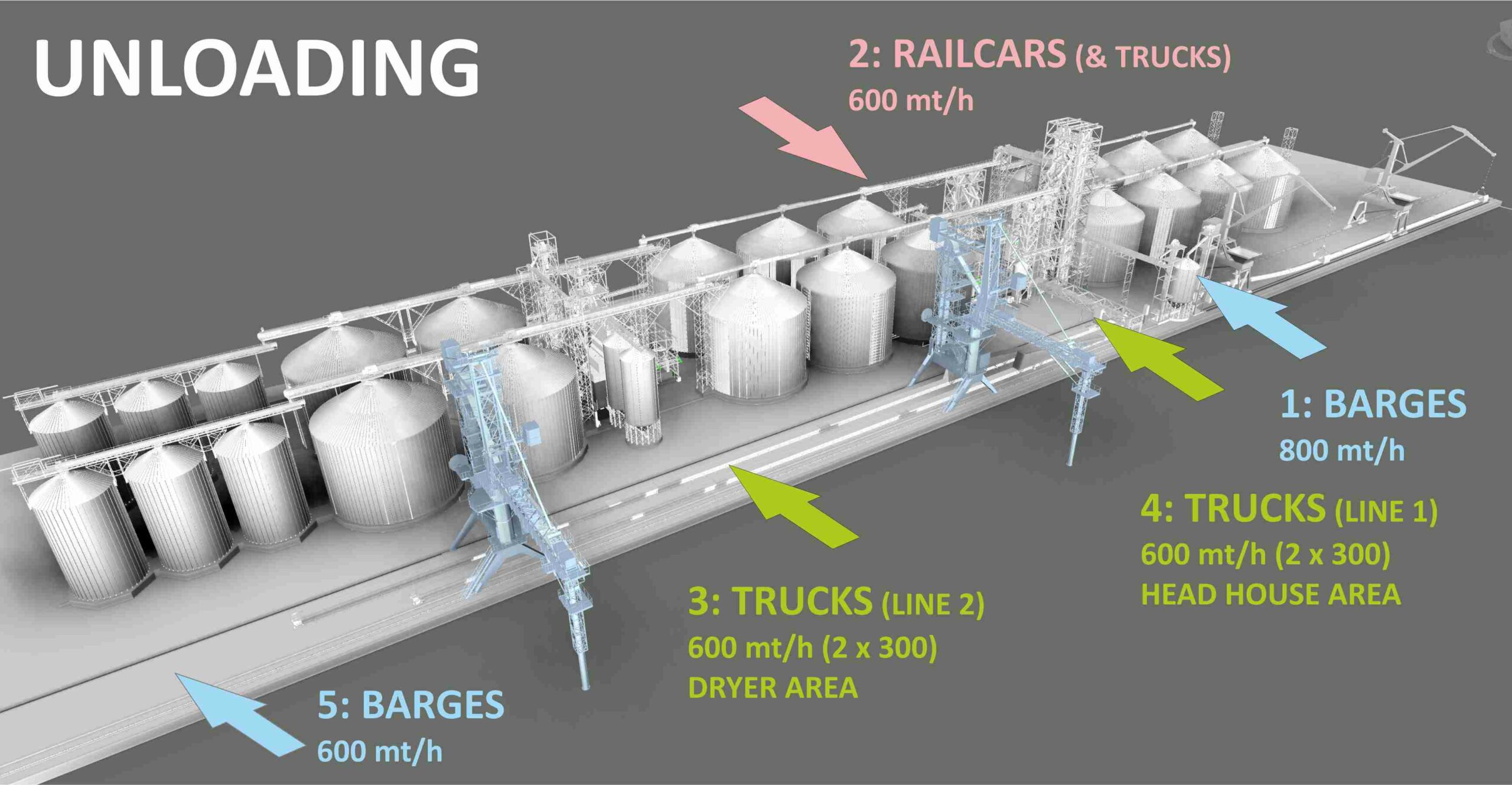

GRAIN HANDLING

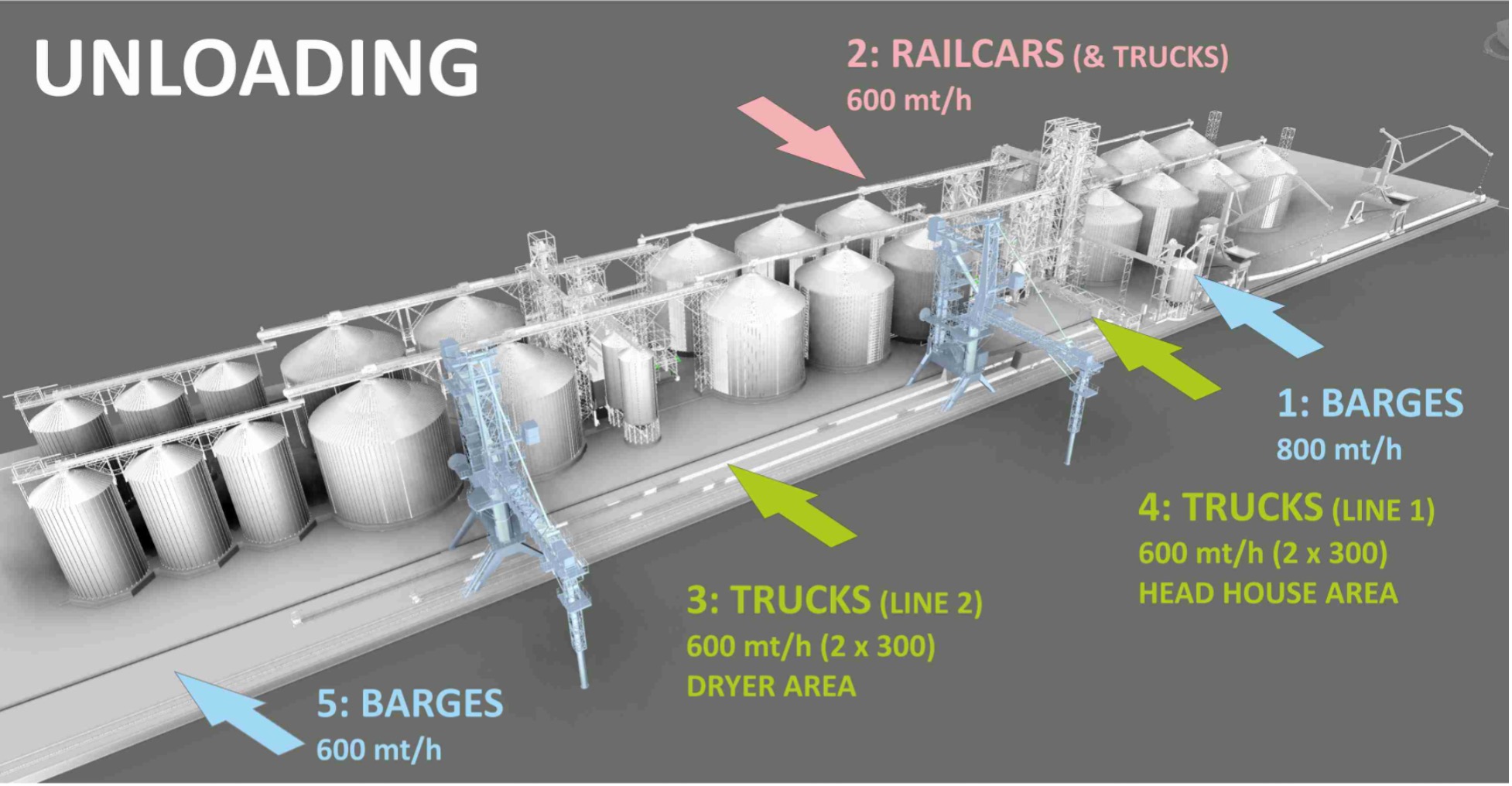

Grains are unloaded from barges, railcars and trucks and loaded onto ships and trucks.

The following nine activities can be performed simultaneously:

UNLOADING / RECEPTION (5 activities)

- Unloading barges: 800 mt/h by two shore cranes with grabs at the berth 80

- Unloading barges: 600 mt/h by two shore cranes with grabs at the berth 81

- Unloading railcars: 600 mt/h at one railway receiving hopper.

The length of the hopper allows simultaneous unloading of two longest railcars. Railway receiving hopper can be used for unloading trucks.

- Unloading trucks at Line 1: unloading capacity rate is 600 mt/h.

- Unloading trucks at Line 2: unloading capacity rate is 600 mt/h.

Each truck unloading line has two separate receiving hoppers, totalling 4 truck receiving hoppers. Total trucks unloading capacity rate is 1,200 mt/h. If railway receiving hopper is free, then trucks can be unloaded in three places with an overall nominal truck unloading capacity rate of 1,800 mt/h.

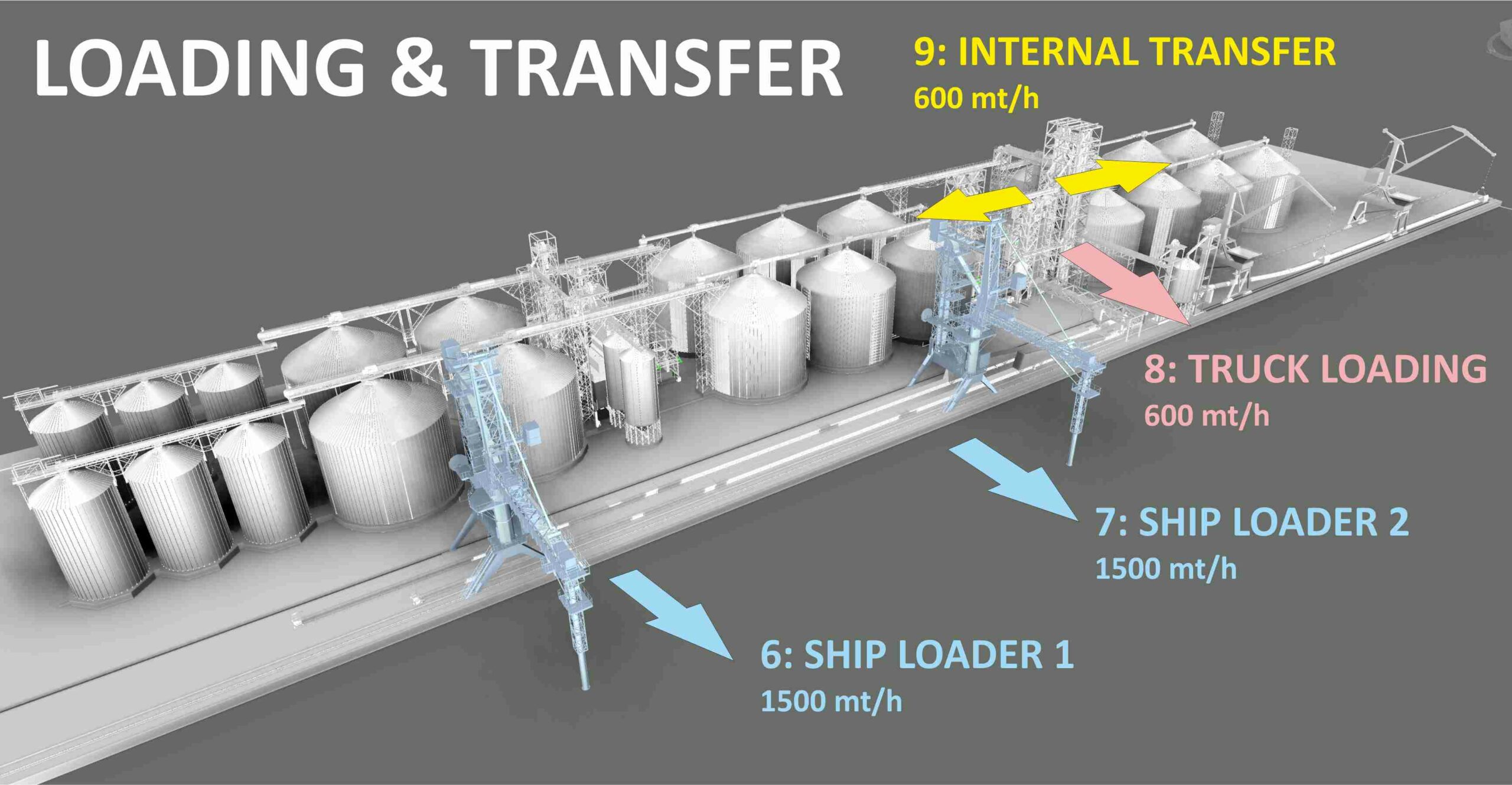

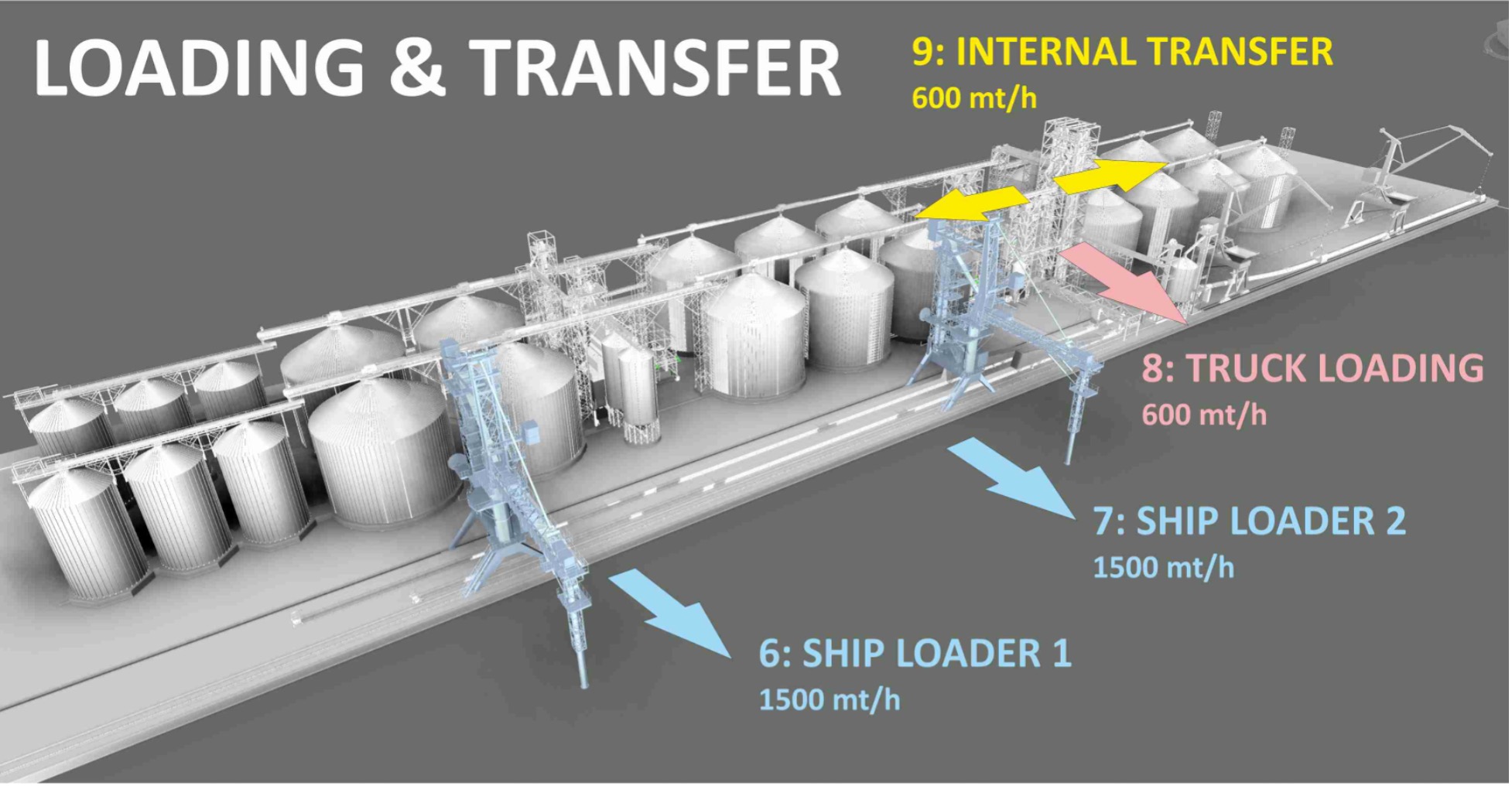

LOADING / SHIPMENT (2 activities)

- Loading ship – line 1: 1,500 mt/h.

- Loading ship – line 2: 1,500 mt/h.

Total ship loading capacity rate is 3,000 mt/h.

- Loading trucks: 600 mt/h.

INTERNAL TRANSFER

- Internal grain transfer: 600 mt/h.

GRAIN HANDLING EQUIPMENT

CGT is equipped with state-of-art grain handling equipment.

The major concern of every grain facility is dust. Through design and equipment selection, CGT opted for completely enclosed conveying systems (belt and chain conveyors and bucket elevators). In addition, at the critical locations spot filters are installed and the trucks receiving areas are aspirated.

These completely enclosed systems, have the following advantages:

- loss of grain is hindered (positive financial impact);

- significant increase of the safety level in enclosed spaces (minimizing the risk of explosion and fire);

- additional costs in operation are not required (maintenance and cleaning); and

- ultimately and the most important, the high-level health protection for employees is provided.

Grain handling equipment is supplied by AG Growth (Canada), worldwide leader in grain handling industry.

AUTOMATION

All equipment, systems and activities of CGT are fully monitored and automated by PC and PLC.

Implementation of SCADA system and full terminal automation maintain efficiency, helps processing data for smarter decisions and communicates issues which help to mitigate downtime. In addition, the implementation of Truck Management System and Terminal Management System minimizes various operational risks and provide smooth terminal operation.

All this together provides CGT’s clients with high quality and reliable services.

SCADA, terminal automation and truck management system are provided by SIEMENS, while inventory management system is provided by BENTO.

Silo bins are equipped with temperature monitoring system and aeration system.

ASCERTAINING QUANTITIES

All the incoming, outgoing and internally transferred grains are weighed by high accuracy electronic scales as follows:

- Barges: two bulk scales, each 600 mt/h;

- Railcars: one scale 120 mt (weighbridge);

- Trucks: four scales, capacity of each: 60 mt (weighbridges);

- Loading ships: two bulk scales each 1,500 mt/h; and

- Internal transfer (recirculation): one bulk scale 600 mt/h.

All five bulk scales are manufactured by CompuWeigh (USA), the worldwide leader in this industry.

The information from the scales is integrated into terminal management system and provides real time monitoring and reporting on all quantities of grain received, shipped or internally transferred.

GRAIN QUALITY

In order to preserve grain quality, all the incoming grain is sampled and the quality is determined prior to unloading for reception approval. Continuous sampling and quality analysis is performed during unloading barges and loading ships.

CGT is equipped with various types of samplers:

- 4 stationary truck probes;

- 1 movable railcar probe;

- 4 cross-cut samplers (two samplers for ship loading lines and two for barge unloading); and

- Manual probes for all transportation means (to be used as required).

Grain quality is monitored in three laboratories:

- Lab1 – barges and ships;

- Lab2 – trucks; and

- Lab3 – railcars.

COMVEX has its own team of laboratory technicians for monitoring the grain quality.

Truck and railcar laboratories are equipped with automated sampling and quality analysis equipment.

GRAIN MIX & BLEND

Equipment arrangement and automation solutions provide the possibility to mix & blend grains from any silo bins based on predetermined client specifications and demands. By meeting particular client’s requirements, CGT is able to add value to the services provided.

GRAIN CONDITIONING

CGT is equipped with both dryer and cleaner. The natural gas-powered dryer has a high-capacity drying rate (drying 100 mt/h with moisture decreasing 5%). As required, grain can be cleaned.

The suppliers of the dryer and cleaner are TORNUM and WESTRUP.

NEW GRAIN SERVICE PROVIDER IN CONSTANTA PORT

As from 2020 COMVEX has extended its bulk raw material handling services to grain. As an already proven reliable partner in ore and coal business, COMVEX has been continuing to provide high quality services to its existent and new clients.